Safe and easy

The selection of the right grease filter for a professional kitchen is a decision that requires careful consideration. The filter plays an extremely important role when it comes to fire safety and protecting the health and lives of the people who work there. The choice of filter also has to do with minimising the risk of major financial losses due to the spread of fire in ventilation ducts. Cyklotec is an excellent choice for increased safety and simplified maintenance. Simply put, Cyklotec is the optimal grease filter for professional kitchens.

Cleaner ducts reduce the risk of fire

The primary function of a kitchen hood is to remove contaminated air. The filter is designed to prevent the accumulation of grease in the exhaust air duct, where it would otherwise become a potential fire hazard. To maintain a correct exhaust air flow in the kitchen, filters must not get clogged with grease and dirt. This entails a major need for regular maintenance, an aspect that can sometimes be forgotten, potentially resulting in food odours escaping into the restaurant area and other adjacent spaces.

We recommend the use of cyclone filters for effective grease separation. They have a significantly greater separation capacity than traditional filters. With cyclone filters, it is also possible to ensure that the right amount of air is always evacuated, as the filter is designed to prevent clogging.

Cyklotec provides optimal filtration

With Cyklotec, we have developed the cyclone filter of the future.

The Cyklotec filter has a very high grease separation capacity, even at varying air flows, which is unique for a cyclone filter. Cyklotec also guarantees that the right amount of air is evacuated, as the filter is designed to prevent clogging.

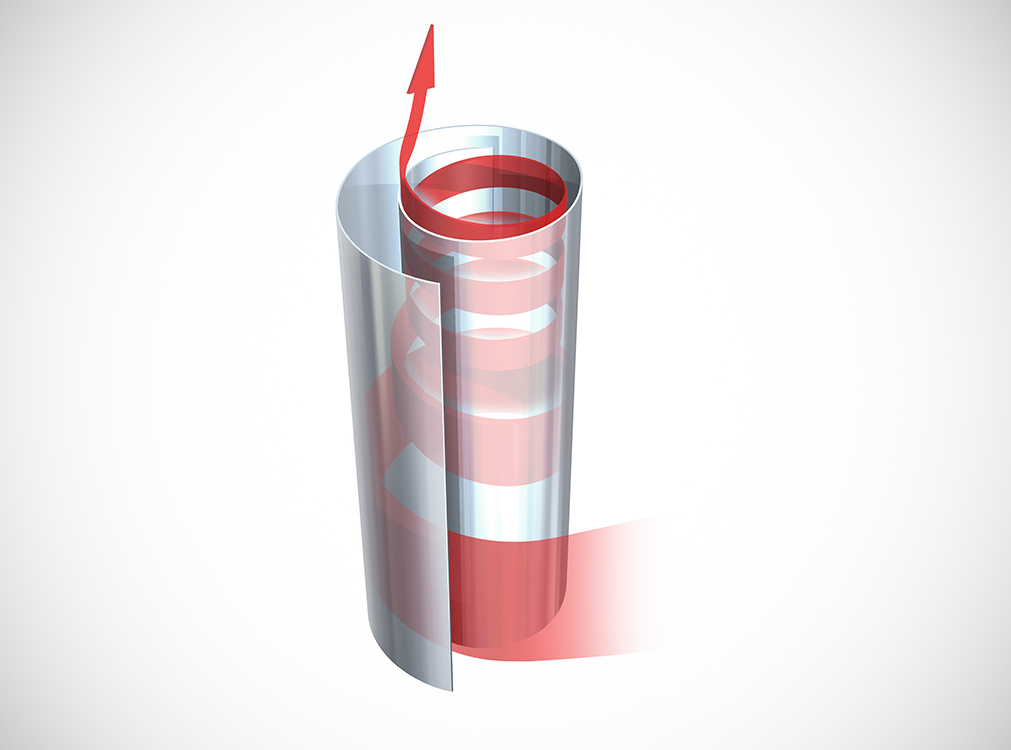

In cyclone filters, the filtration process is achieved by subjecting particles to centrifugal force. This forces the particles against the surface of the cylinder cover, where they condense and run down into the filter’s collection vessel.

The higher the speed, the greater the centrifugal force and filtration effect. Cyklotec’s filter cylinder has a unique spiral design (hyperbolic) that creates an accelerated air speed. The aerodynamic design provides much higher air speeds, even at low air flow rates. This is the secret behind Cyklotec’s superior performance. Furthermore, Cyklotec performs its function without any electric motors or moving parts.

Also perfect for variable flows

Effective reduction of the amount of grease in a professional kitchen’s exhaust air is crucial for the achievement of minimised fire load and duct cleaning requirements. Cyklotec separates all particles larger than 7 µm at the recommended flow rate and 9 µm at half flow. Therefore, unlike traditional cyclone filters, Cyklotec can be used with a retained level of particle separation in kitchens where fans are used at both full and half speed.

Since each filter cassette functions within a wide flow rate range, the kitchen’s filtration requirements are normally met with just a few cassettes in the kitchen hood. This also makes maintenance easier, as fewer cassettes need to be removed for cleaning in a dishwasher.

- Air containing grease flows into the cyclone

- When the air circulates at a great speed in the cyclone, the grease and particles are hurled against the walls of the cyclone due to the centrifugal forces exerted

- Grease and grime drip down the walls to the filter’s collection vessel

- The filtered air flows out of the cyclone filter and is transported into the exhaust air duct

Each filter cassette consists of ten cyclones. The cassettes can be easily removed for cleaning in a dishwasher.